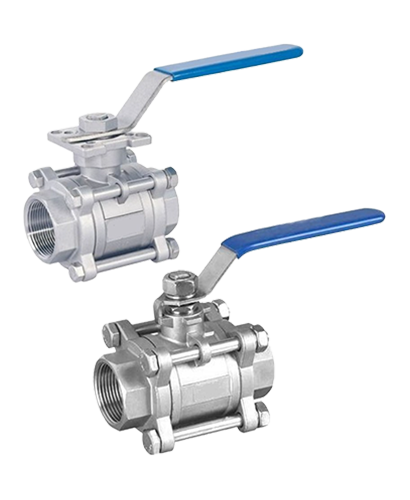

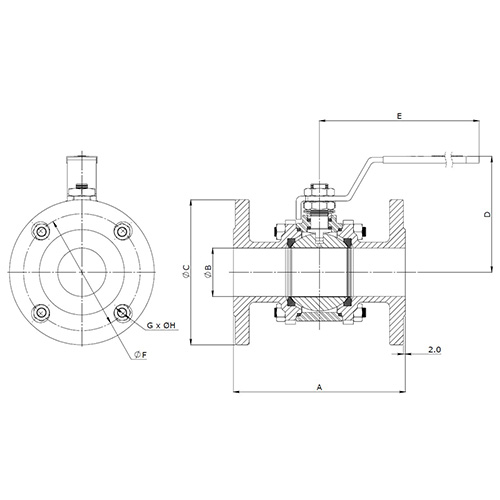

FLANGED BALL VALVES

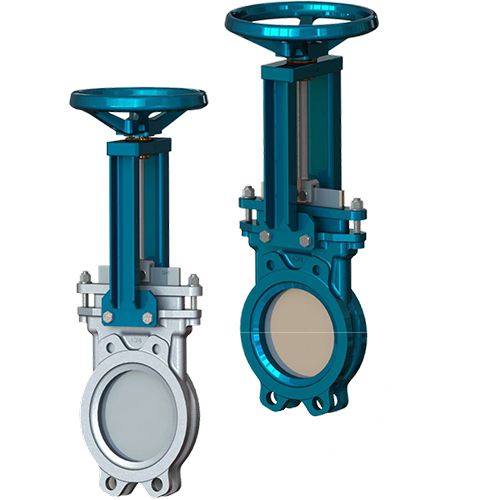

Body Parts are of investment casting, normalized for added strength, and marked with a HET number for full traceability. Carbon Steel bodies are phosphate coated for increased corrosion resistance.

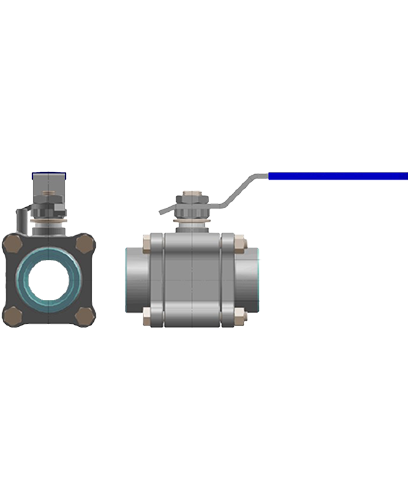

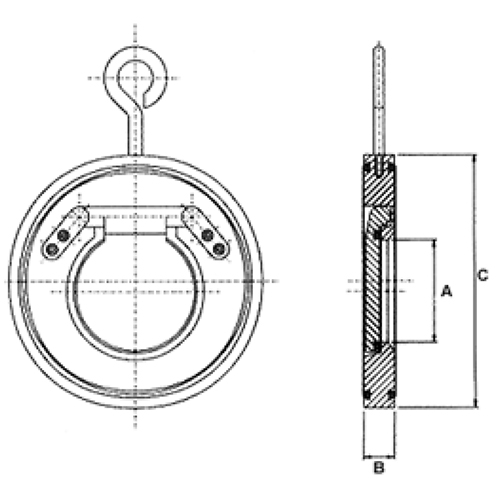

The Ball, Seat, and Stem are precision machined for bubble-tight shut-off and less operating torque. Balls are of mirror finished. Seats feature relief slots to relieve pressure, and stems are heavy-duty blowout-proof, with double "D" connections to the ball and operator mounting.

The Stem Seal automatically adjusts and acts as a secondary seal between the stem and body.

Stem Packing An adjustable V-ring design creates multiple seals between the stem and body.

Secure Mount Flanged Series Valve offers ease of automation due to a dedicated ISO pad that complies with 5211 and is integral with the body.

Locking Devices feature a locking arrangement through a padlock to secure the handle in position to prevent accidental movement of the ball.

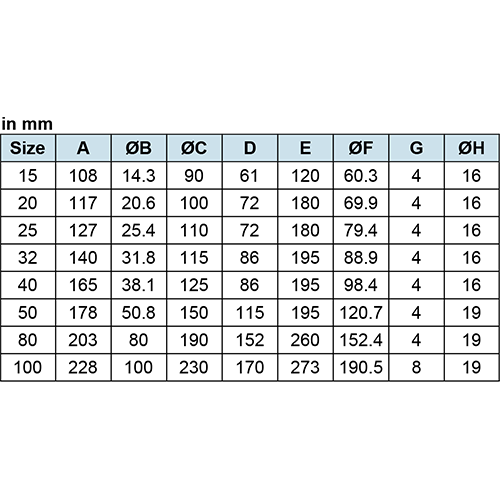

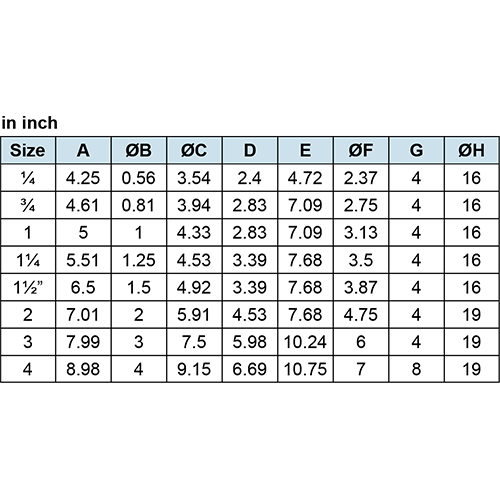

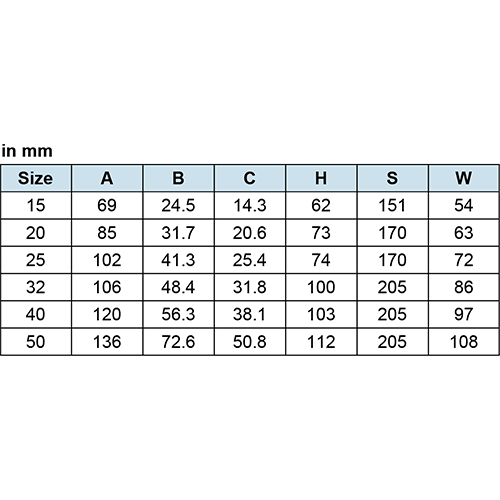

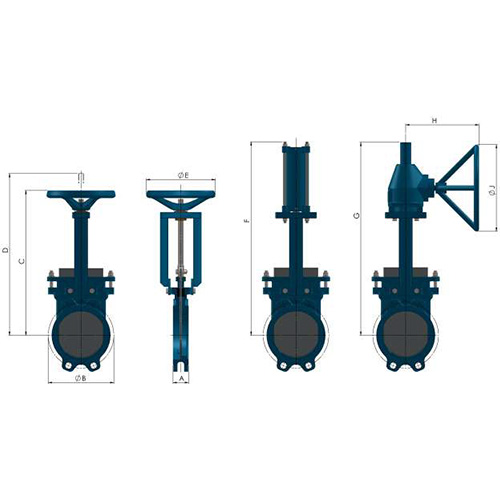

| Technical Specification | Size range: DN15-DN100 Body style: Three piece End Connection: Flanged Pressure rating: Class #150 Drilling: ASME B16.5 #150 Face to Face: ASME B16.10 Design std.: ISO17292, ASME B16.34 Testing std.: EN12266-1, API598 |

| Standard MOC Option | Body: WCB / CF8 / CF8M Ball: SS304 / SS316 Seat: PTFE STEM: SS304 / SS316 Port: Reduced / Full Operator: Manual / Non-manual Specials: Anti-static & Firesafe Option: ISO / Non-ISO |